POLISHED CONCRETE FLOOR

POLISHED CONCRETE FLOOR

What is a polished concrete floor, exactly?

Polished concrete is a premium finish created directly from your existing concrete slab. It’s not a coating or a product applied on top, but a true transformation of the surface itself. Through mechanical grinding, chemical densification, and precision polishing, we reveal the inner strength and natural beauty of the concrete.

No coatings. No overlays. Just a smooth, dense, glossy finish that becomes one with the slab. Unlike epoxy or sealers, polished concrete won’t peel or delaminate. It’s permanent, seamless, and low- maintenance.

This service is offered by select certified B.Protek Concrete Coatings franchise owners, depending on your location.

THE 3 KEY STEPS TO TRANSFORM YOUR INDOOR CONCRETE FLOOR WITH A POLISHED CONCRETE

Speak with a Specialist

Call us today to discuss your project and confirm its feasibility with a B.Protek expert.

Schedule a Free Consultation

One of our experts will visit your space to assess your floor, understand your needs, and plan the next steps with you.

Transform Your Space

Transform Your Space

Our franchise partners complete the transformation of your floor within just a few days, depending on the surface and finish you choose.

Speak with a Specialist

Call us today to discuss your project and confirm its feasibility with a B.Protek expert.

Schedule a Free Consultation

One of our experts will visit your space to assess your floor, understand your needs, and plan the next steps with you.

Transform Your Space

Transform Your Space

Our franchise partners complete the transformation of your floor within just a few days, depending on the surface and finish you choose.

Get a quick estimate for your polished concrete project

Why choose polished concrete?

- THE BENEFITS

- HOW IS POLISHED CONCRETE DONE?

- WHERE DOES POLISHED CONCRETE WORK BEST?

- FINISH LEVELS AND AESTHETIC OPTIONS

- LOW-MAINTENANCE, HIGH-PERFORMANCE FLOORING

- Modern, mineral finish available in matte, satin or gloss

- Superior durability and resistance to wear

- Easy maintenance, no waxing or specialty cleaners

- No embedded dust or flaking surface

- Low environmental impact: zero VOCs, no added resin

- Excellent long-term value

We follow a three-step professional process:

Mechanical Grinding

The surface is ground using industrial diamond segments. The depth of grinding determines the level of aggregate exposure:

- Grade 1 – Cream finish (no exposure)

- Grade 2 – Sand exposure

- Grade 3 – Partial or full aggregate exposure

Chemical Densification

A lithium- or silicate-based densifier is applied to fill pores and harden the concrete.

Progressive Polishing

The surface is polished with increasingly fine diamond pads to reach the desired sheen: matte, satin, or high-gloss.

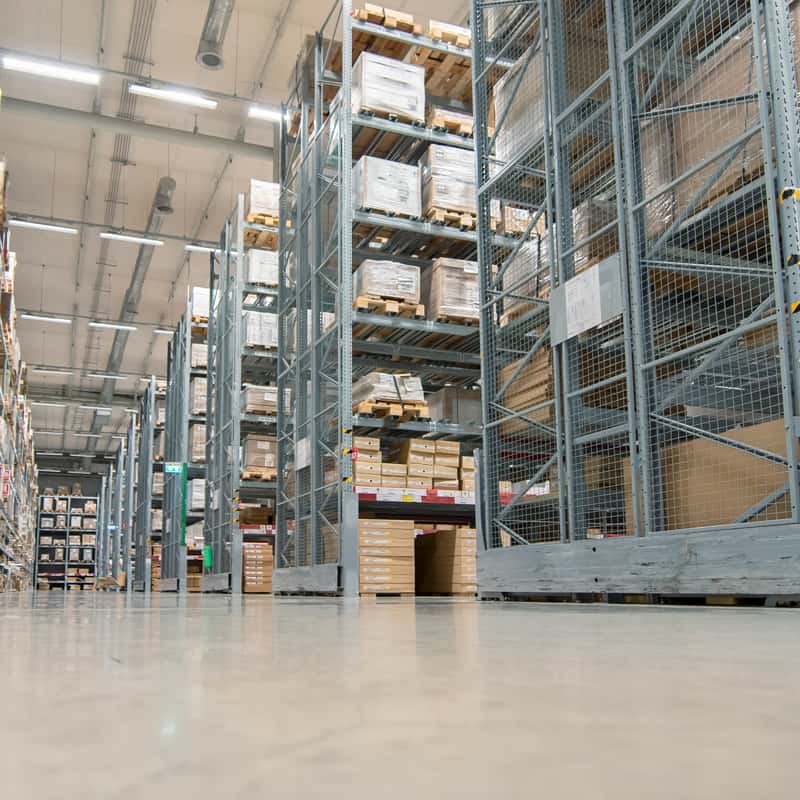

Polished concrete is ideal for indoor spaces with an exposed slab:

- Residential: basements, lofts, kitchens, hallways, entrances

- Commercial: offices, stores, showrooms, museums, lobbies

- Light industrial: dry warehouses, clean workshops, production areas

Polished concrete can be customized based on the exposure level and finish you’re looking for:

Grade 1 – Cream finish: smooth and uniform, no visible aggregates.

Grade 2 – Sand exposure: exposes fine sand particles for a subtle, elegant texture.

Grade 3 – Full aggregate exposure: reveals the larger stones in the concrete, for a distinctive architectural look.

All finish levels can be delivered in matte, satin or gloss.

| Maintenance Type | Main Action | Recommended Frequency |

| Routine Cleaning | Dry dust mop or auto-scrubber with non-abrasive pads. | Daily to weekly, depending on use |

| Damp mop with pH-neutral cleaner (no acidic or harsh degreasers). | ||

| Periodic Cleaning | Deep clean using diamond pads (e.g., Twister) to refresh the finish. | Monthly to quarterly |

| Inspect for dull areas, micro-cracks or localized wear. | ||

| Preventive Care | Light repolishing with fine diamond pads to restore shine. | Every 6 to 12 months |

| Reapply protective sealer (if originally used). |

Simple upkeep. No harsh chemicals. Just lasting beauty.

B-Protek Excellence at a Glance

10,000+ floors transformed

10,000+ floors transformed

With over 10,000 resurfaced concrete floors under our tool belts, our experience speaks for itself.

Canadian-Made products

Canadian-Made products

Using Canadian-made products allows us to support local and ensure top-notch quality.

24-hour turnaround time

24-hour turnaround time

Our hard-working and speedy teams can often complete installation in less than a day.

Service areas across the country

Service areas across the country

Our teams are readily available throughout Canada, no matter where you are located.

10,000+ floors transformed

10,000+ floors transformed

With over 10,000 resurfaced concrete floors under our tool belts, our experience speaks for itself.

Canadian-Made products

Canadian-Made products

Using Canadian-made products allows us to support local and ensure top-notch quality.

24-hour turnaround time

24-hour turnaround time

Our hard-working and speedy teams can often complete installation in less than a day.

Service areas across the country

Service areas across the country

Our teams are readily available throughout Canada, no matter where you are located.

Real-life examples

A turnkey project, delivered locally

Our certified B.Protek Concrete Coatings franchise owners assess your slab’s condition, moisture level, intended use and design preferences. Every project is handled with care—from preparation to final finish.

Request your free quote today and find out if polished concrete is right for your space.

FAQ – Polished Concrete

No. Even with a glossy finish, it maintains strong traction and is often safer than a painted or sealed floor.

Yes, as long as the slab is structurally sound. We’ll inspect it and recommend repairs before polishing.

Pricing depends on the surface condition, finish type and area. Ask your local B.Protek franchise for a custom quote.

No harsh chemicals. Polishing is mechanical. We use only safe densifiers and emit no VOCs or solvents.

No. Polished concrete is for indoor dry spaces only. For garages, we recommend our polyaspartic flake system.

Get a quote in under 2 minutes!

Our online tool gives you an instant no-pressure estimate for your concrete resurfacing project.